CEO Martin Meier explained that in addition to sustainability as the core requirement of the development team’s strategy, they wanted to make the glueing process simple, reliable and efficient.

Martin Spalinger, director of Strategic Marketing & Innovation, added that the Vision melter gently melts demanding thermoplastic hot-melt adhesives, maintains a constant adhesive viscosity, and conveys hot-melt at a consistent pressure to the application head. ‘This significantly increases the reliability during high-precision adhesive applications, which is particularly needed when glueing primary packaging. Compared to the Concept predecessor model, Vision requires 20% less energy,’ he noted.

The Smart Terminal displays current operating and status information in changing colours via an LED strip on the device. Displays of the pump pressure, status codes, and four function keys facilitate operation and rapid intervention. ‘Even from a distance, operators can recognise whether the glueing process is running smoothly or whether, for example, they need to refill the adhesive,’ claimed Martin.

The melter can be installed lengthwise or crosswise and is operated remotely or via the optional Touch Display screen. The FlexPort connection surface allows heated hoses to be connected at different angles to save space. This gives customers the flexibility to position it at the shortest possible distance from the application heads, keeping the heated hose length short.

It is complemented by the Robatech Control System, a platform that offers open interfaces and standardised Fieldbus protocols for easy integration into complete systems.

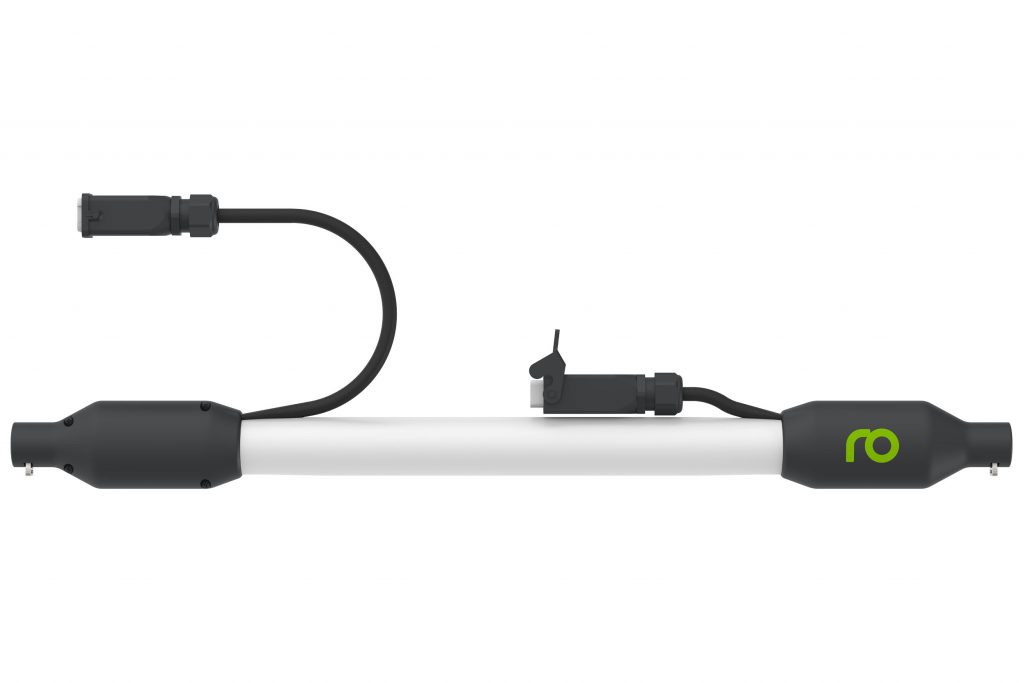

The second development launched during the event was the Performa heated hose, which can be used with Concept series melters in combination with Enduro heated hoses.

‘Performa is equipped with PrimeConnect plug coupling, which sets a new trend for plug-and-play connection of heated hoses,’ Martin explained. ‘The PrimeConnect system is fully insulated, eliminates standard thermal bridges, and ensures that the adhesive viscosity remains constant at the connection points to the melter and application head.’

Compared to Robatech’s Enduro heated hoses, Performa uses up to 45% less energy and is suitable for viscosities from 100 to 20 000 mPas.

Robatech also launched SpeedStar Compact as the successor to the SpeedStar, an application head for precise adhesive application at high production speeds.

SpeedStar Compact (pictured right) enables high-precision hot melt adhesive application through its fast opening and closing speeds. Martin noted that the electric jetting head can precisely position tiny dots (up to 800 dots/second) and small beads, even at very high production speeds, thanks to its switching frequency of 800Hz.

‘We are excited to offer this technology to the local industry,’ said Robatech SA MD, Dominique Schlenk. ‘Not only does the new design look great, it also offers energy-efficient features and first-class usability – truly the new dimension in glueing.’

Click here to read in the E-mag.

![02 GSW WideFormat [2]](https://www.packagingmag.co.za/wp-content/uploads/2024/11/thumbs/epic-350x250/02_GSW-WideFormat-2-350x250.jpg)