The industry has been talking about these global trends for years and now it is statistically proven that the ‘one size fits all’ era is gone. The percentage of the population interested in personalisation has increased rapidly over the years, with the boomer generation currently sitting at 27%, Gen Xers at 32%, millennials at 45% and Generation Z representing 53% of the addressable market interested in personalisation.

According to research by Sparks and Honey, the personalisation market is worth $201-billion, an increase of 49% from 2021. Furthermore, 70% of shoppers are willing to pay more for a personalised item.

The Covid-19 pandemic and the resultant supply chain challenges and rising material costs have also accelerated change. ‘Companies can no longer afford the kilometres of material waste associated with analogue set-ups. Nor can they afford massive stock holdings with products that may or may not sell, which means that the drive for digital just-in-time production is becoming more prevalent by the day,’ explains Angelique Greer, Midcomp Group’s marketing director.

Brand differentiation and personalisation have also been bolstered over the past two years by people having become entrepreneurs out of necessity after losing their jobs or sitting at home in quarantine thinking/plotting that there has to be more to life than working for someone else. They have subsequently created ideas like delivering ready-made meals to consumers’ doors or producing microbrews, medicinal cannabis, vape consumables and many other products.

These entrepreneurs realised that with the adoption of e-commerce they didn’t need a shopfront anymore, they could simply sell online. The growth in small online retailers, crafting businesses and bespoke brands has meant an increasing need for high-quality short runs as their products have to look and feel world-class to remain competitive.

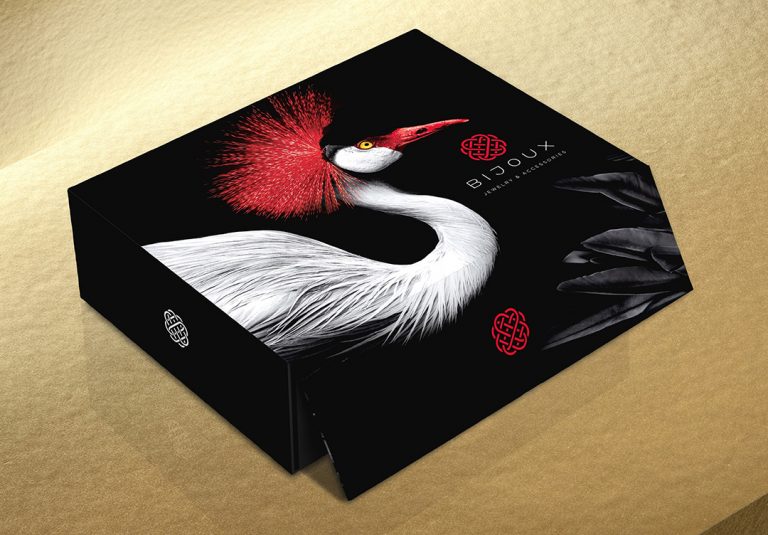

Brands know that personal messaging and high-quality packaging help boost consumer engagement. This is an important factor with the rise of e-commerce – projected by Smithers to grow to $7.4-trillion by 2025 – as more and more branded and tailor-made products fight for customers’ attention.

Brands also realise that the unboxing experience video trend – customer reviews in a visual format that lead to more sales – has transitioned into everyday life, making the packaging experience a must-have rather than something that brands use to differentiate themselves.

Another complementary trend is shorter product life cycles and more versions as consumers demand greater choice and want to demonstrate their uniqueness by choosing small, craft players. These demands are also resulting in brands offering more products and variations in their portfolio to capture new market segments. For example, in Japan, there are over 200 versions of KitKat, and the packaging requires more variation as the number of versions increases.

Digital diversity bolsters short-run production

However, supplying packaging and labels for entrepreneurial, craft and bespoke brands has been a barrier to entry for traditional packaging converters with analogue equipment geared for long runs with high set-up costs and minimum order quantities.

Midcomp believes packaging converters should embrace digital printing and finishing equipment as it best addresses the needs of this short-run entrepreneurial market. ‘Converters should allow digital technologies to complement their existing arsenal of analogue infrastructure such as lithographic, flexographic and gravure presses or platen and rotary die cutters,’ Angelique recommends. ‘Doing this will expand their addressable market, shorten turnaround times from weeks to hours, reduce waste, improve margins and allow for rapid prototyping. Most importantly, the intangible value of “can do innovative work’’ will solidify relationships for the future. After all, think of how many new products are popping up with rapid success and going from tiny to long runs in just months. Short-run digital is merely an investment in a long-run customer for the future in an age where customer retention and sustainability are the keys for success.’

Angelique cites the HP Latex R Series Hybrid flatbed printer and HP PageWide XL Pro Series as two digital-enabling technologies. For large board printing production, she describes the HP Latex R Series as a wide format production printing press using water-based inks for reasons of food compliance. ‘It is an ideal production printer for rapid prototyping and printing of short-run carton and corrugated packaging.’

‘For smaller board formats, the PageWide XL Pro series also features end-to-end cut-sheet workflow, which allows users to print two-sided on cut sheets, as well as HP’s large-format auto sheet feeder and versatile high-capacity stacker. The XL Pro uses a variety of types and sizes of paper, cardstock and boards, from A2 up to B1 in size, and can print on rigid stock that’s up to 10mm thick,’ says Angelique. ‘Its ability to print large areas of solid colours in approximately three seconds enables converters to produce printed bespoke gift boxes in a day instead of a week and to offer a broader basket that includes standard or double-sided hanging promotional posters, branding and marketing materials.’

She points out that with today’s digital printing capabilities, speciality folding carton and corrugated gift boxes, welcome packs and retail-ready packaging can truly stand up to the competition in the retail aisle and capture some huge speed-to-market benefits via high-impact customisation. Flexible HP Latex inks enable better folding and bending without cracking compared to UV ink-based technologies.

Angelique adds that innovative point-of-purchase displays, which contain a product with marketing material, are strategically located throughout a retail store to grab shoppers’ attention. ‘High-quality, customised corrugated displays printed with vibrant colours help extend branding awareness beyond the product’s shelf – helping it stand out from the competition by increasing its points of interest and visibility,’ she concludes.

Click here to read this article in the E-mag.