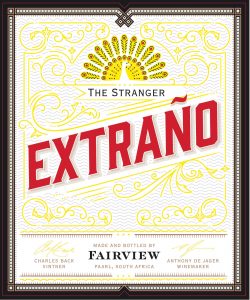

‘The label is an integral part of the packaging as it enables a product to stand out from its competitors. The printing and supply thereof are a time-critical, precision business in which quality must never slip,’ comments executive director, Keith Vroon.

LPL specialises in self-adhesive wine label printing through UV flexo, digital printing and finishing technologies. The company’s inline finishing options include cold and hot foiling, screen printing, laminating, UV varnishing, die-cutting, debossing and embossing.

‘Our capabilities extend to printing security holograms on labels, back printing and other specialised printing features,’ explains Keith.

According to general manager, Henk Jacobs, printing with quality papers and finishes will increase the shelf appeal of a wine label. ‘To help our customers meet their sustainability needs, we offer a growing selection of environmentally sustainable label material options including recycled content, plant-based renewables, compostable and biodegradable materials.’

LPL’s exclusive Treefree paper, supplied by UPM Raflatac, offers everything expected from a premium quality wine label while being environmentally friendly. It’s an uncoated paper manufactured from sugar cane fibre (bagasse), a by-product of the sugar refining process and a fully renewable source. It offers the performance of a premium quality wine label paper without chopping down a single tree and is recyclable.

‘Treefree has a natural texture with a soft earthy colour. For a different background colour, a subtle buff colour of choice can be added,’ comments Henk.

Weighing in at 110g/m2, Treefree offers great opacity and trouble-free production on application lines. ‘It lends itself to any of the value-added processes such as hot-stamp foiling and screen printing and performs exceptionally well in ice buckets, retaining its good looks and adhesive qualities in damp and cold conditions,’ he explains.

Henk asserts that the local wine industry is thriving again after the massively negative impact of the alcohol bans. ‘We’ve noticed that the demand for premium, uncoated wine labels has increased, driven by exports of local wines.’

Keith adds that LPL has seen tremendous growth over the last couple of months. ‘We’re proud that our customer base has grown during this period, and we always strive to provide the best quality products and services,’ he states. ‘We work closely with customers through each process, guiding and supporting them by providing expert advice on various aspects of labelling.

‘Wine brands that can tell stories effectively through their labels are able to command the market. To do this effectively, it is important to understand how to maximise the impact through the wine label printing and finishing processes,’ concludes Keith.

Click here to read this article in the E-mag.