‘In this industry, selling machines is just the start – keeping them running is where the real value lies,’ Sivan comments. ‘We don’t believe in leaving customers waiting for days for support. We aim to respond within 48 hours and have grown our technical team to ensure this. Our rapid-response service – often within 24 hours – is what truly sets us apart.’

According to Sivan, they don’t just fix problems, they prevent them. Techplas Services’ planned maintenance contracts ensure machines keep running at peak efficiency, so customers can focus on production, not downtime.

Techplas Services has built its reputation on delivering tailored solutions across PET preform systems, single- and two-stage injection stretch blow moulding, injection moulding, extrusion blow moulding – covering PVC, PP and HDPE – and automation. Now, with a game-changing addition to its portfolio, the company is poised to take another major leap forward.

Landmark deal: exclusive agency for CNHAO

In March, Techplas Services secured the exclusive distribution rights for CNHAO, a Chinese-based manufacturer renowned for its turnkey plant planning, eco-friendly solid waste recycling systems and ancillary equipment for the plastics industry.

‘This is a massive win for us,’ Sivan explains. ‘CNHAO’s range of shredders, granulators and cooling tower systems fills a crucial gap in the South African market. The OEM offers an affordable yet high-quality solution – Chinese engineering has advanced significantly over the last decade. We’re confident that CNHAO will be a unique differentiator for local recyclers and converters.’

Beyond affordability, CNHAO’s ability to provide customisable solutions makes it an attractive proposition for businesses seeking efficiency and sustainability. The brand’s expertise in handling both flexible and rigid plastics, as well as wood and metal, positions it as a versatile solution for a market hungry for innovation.

Techplas Services is also making waves with the launch of its own branded single-stage ISBM equipment. Through a strategic partnership with an established Eastern-based technology supplier, Techplas has introduced the TSB 520 and TSB 550 models – high-performance, cost-effective machines designed to make ISBM technology more accessible to South African manufacturers.

‘This is a proven technology,’ Sivan asserts. ‘Our partner has seen success in markets like Mexico, the Asian subcontinent and parts of Europe. Now, we’re bringing it to South Africa under our own brand, offering customers a reliable, servo-driven solution at an exceptional price point.’

Power of precision

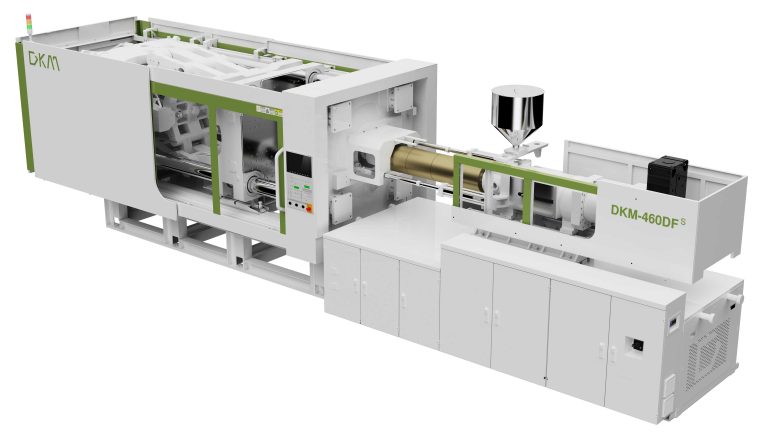

Techplas Services is also the official distributor of Dakumar’s range of injection-moulding machines, a brand that has earned global recognition for its energy-efficient and high-speed solutions. At Propak Africa 2025, the company officially introduced the Dakumar DFS series – an injection-moulding machine tailored for thin-wall food packaging.

‘This machine is a game-changer,’ Sivan enthuses. ‘It features low-inertia technology, servo-driven systems and infrared heating, all designed to maximise efficiency. The plasticisation unit is servo-driven, allowing parallel plasticisation during mould cooling and opening. The result? Faster cycles, lower energy consumption and increased productivity.’

Techplas Services is currently running a limited-time ‘launch discount special’ on this machine, as well as the ISBM, SMC EBM, caps folding and slitting equipment, high-speed fully automatic packaging and bagging machines and CNHAO range – an enticing proposition for businesses looking to invest in cutting-edge technology at competitive pricing.

Automation: the Alfa edge

Automation is transforming the plastics industry, and Techplas Services has positioned itself at the forefront of this shift with its distribution of the Alfa range of robotic automation systems.

‘We’ve supplied several units to multinational corporations over the past three years,’ Sivan reveals. ‘Their repeat business speaks volumes. Our robotic solutions streamline operations, reduce labour costs and enhance precision, making them a key component of modern plastics processing.’

Techplas offers a variety of robotic solutions, including high-speed take-out, mould inserts and pick-and-place robots, as well as six-axis robotic systems for intricate automation tasks. The company ensures full local backup service and critical spare part availability, reinforcing its customer-first approach.

High-quality solutions

Another key principal in Techplas’ portfolio is Xinzheng, which supplies high-speed packaging lines, palletisers, leak testers and weight checkers.

‘The response at Propak Africa was incredible,’ Sivan notes. ‘Visitors were particularly interested in our fully automatic bagging machine. Xinzheng’s solutions complement our broader strategy of offering cutting-edge technology to the South African market.’

The demand for high-quality extrusion blow-moulding equipment is rising, and SMC, another Techplas principal, is stepping up to the challenge. With a manufacturing centre in Thailand, SMC custom-builds machinery to individual customer specifications, capable of processing polypropylene, HDPE and PVC to produce bottles ranging from 20ml to 60 litres.

Techplas also represents Tinko, a specialist in hot runner temperature control systems. ‘Tinko’s temperature control solutions are a major differentiator,’ Sivan explains. ‘This technology features an advanced alarm system that detects blocked nozzles in the mould, preventing material from being pushed back into the manifold and allowing converters to take corrective action immediately.’

Future of Techplas

With an expanding portfolio and a commitment to exceptional service, Techplas Services is well on its way to becoming a dominant force in South Africa’s plastics processing sector. Whether it’s through its exclusive partnership with CNHAO, its launch of new ISBM technology or its representation of world-class brands like Dakumar, Alfa, Xinzheng, SMC and Tinko, Techplas is proving that technical excellence and customer-centricity go hand in hand.

As the company gears up for further expansion, Sivan remains steadfast in his vision. ‘We’re not just supplying machines – we’re providing solutions. Our mission is to add value at every stage of the production process, ensuring our customers stay competitive in an evolving industry.’

For Techplas Services, the future isn’t just about keeping up with industry trends – it’s about setting them.