It’s big, very big! Producing the largest sizes of flexo plates, the new line-up at Africa Stereos includes Concept 501 exposure and dryer units, complemented by a Concept 505 DW XP digital washout unit. The latter (pictured above) offers extended length washout, featuring 22 brush rollers for increased washout speeds and a prewash for black layer removal.

IN South Africa’s ever-changing and highly-demanding flexographic industry, Africa Stereos clearly counts among the frontrunners in its commitment to keeping pace with advances in technology, striving to provide the best possible platemaking service and quality products.

For more than two decades, this Cape Town-based business has grown steadily to become a major supplier of plates, primarily to the corrugated industry, but increasingly moving into the fields of roll-label, shrink label and flexible packaging.

Reaping the rewards

Underlining the company’s strong position in the corrugated sector, it was named as the platemaker in four award-winning entries in last year’s FTASA Print Excellence Awards. Africa Stereos’ customers walked off with two gold awards, one silver and one bronze.

Over the years, under the highly-experienced direction of MD, Sean Drake, continual investments have been made to cope with the stringent demands of an increasingly sophisticated flexographic printing fraternity.

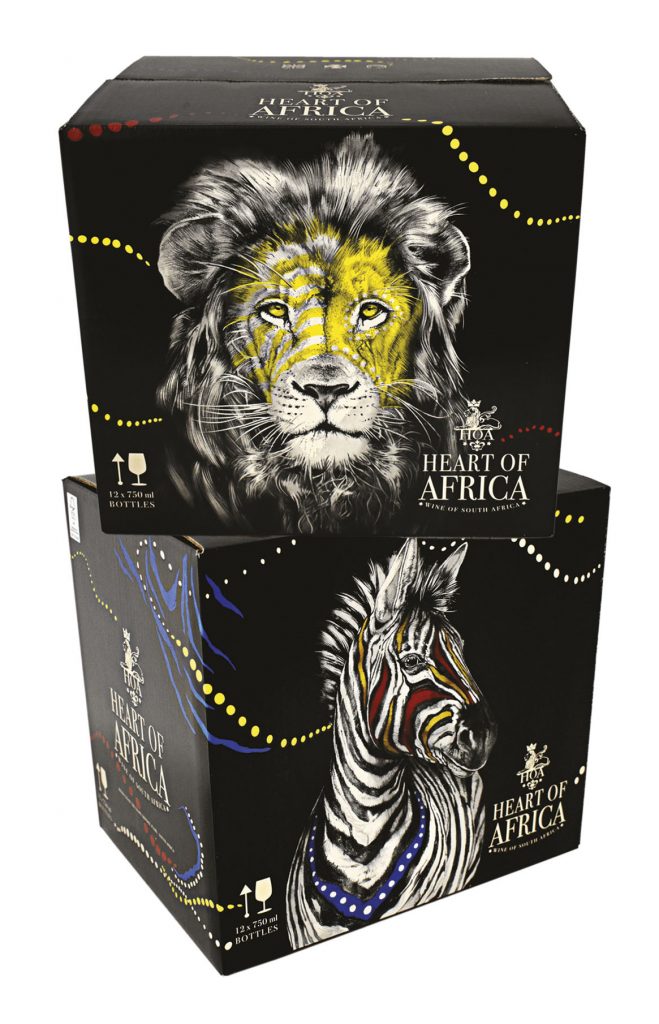

This stunning carton took a gold medal in last year’s FTASA Print Excellence Awards. Using spell-binding visuals, it’s printed by Mpact Corrugated (Epping) using MacDermid plates and plates from Africa Stereos. This beautiful print is achieved using four spot colours plus black. This was just one of the four award winning entries where Africa Stereos was named as the platemaker.

The Glunz & Jensen Concept 501 exposure and dryer units are adding greatly to Africa Stereos’ ability to supply the plates required for the production of award-winning corrugated packaging.

Celebrating a decade of LUX Flat-Top Dots

MACDERMID Graphics Solutions (MGS), a world leader in the manufacture and marketing of photopolymer plates and platemaking equipment for the flexographic printing market, is celebrating 10-years of LUX flat-top dots.

From its innovative lamination systems, launched in 2010, to its award-winning inherently flat-top dot plates, MGS continues to market these well-proven print benefits to the global package printing industry, and locally through TAD Printing Products.

MGS’s digital photopolymer plates are available in a variety of options, including hard, medium and super-soft on the durometer scale. These plates are used in numerous package printing applications, including flexible packaging, tags & labels, folding cartons, multiwall paper bags and corrugated containers.

MGS prides itself on supporting customers – from packaging concept through to the final on-shelf product – with unparalleled technical assistance, equipment and innovative technology.

‘We’ve always been known for high-quality production, and high-quality service to our customers,’ Sean remarks. ‘And now, with our latest round of investments, we’re taking repro to the next level, particularly for the production of upmarket corrugated packaging.’

The new line-up consists of a Glunz & Jensen Concept 501 exposure and dryer units, complemented by a G&J 505 DW XP digital washout unit, and a Heights S-Line 52 light finishing unit – all supplied by TAD Printing Products.

The G&J 505 DW XP is an extended length washout, featuring 22 brush rollers for increased washout speeds and a prewash for black layer removal. The 501 is G&J’s largest exposure platform for flexo plate sizes up to 1 320 x 2 030mm. The unit includes cooled bed, lamp cooling, light integrator and PLC control. Automated top lid opening/closing is a standard feature.

This impressive processing equipment joins three existing imaging devices (two Kodak ThermoFlex Wide and a Screen PlateRite FX) and also replaces some smaller units.

Investments bring fresh levels of efficiency

‘This new equipment is adding to a fresh level of efficiency,’ Sean reports. ‘Our plate processing equipment now includes two 50×80 exposure units, the new 50×80 washout unit and an existing 42×60 washout unit; and we now have two 50×80 dryers and two 50×80 light finishers.

In a nutshell, Africa Stereos can now washout the largest size flexo plates in just 15 minutes, translating into ultra-fast service for customers.

TAD Printing Products was responsible for the supply and installation of the new equipment in mid-February. Commissioning was managed in three days by TAD’s Patrick Krieling and Ibrahim Dempers, with assistance from Adrian Gildenhuys, followed by a further day’s training.

As Africa Stereos production personnel are already extremely competent in all areas of platemaking, this training primarily centred on aspects of the new equipment’s user interface.

Rounding out the services offered by Africa Stereos is a well-equipped design department, allowing customers a one-stop shop for graphic design, repro, digital imaging, proofing and platemaking.