Student wine label design competition

ROTOCON has launched a wine label design competition in partnership with the Tshwane University of Technology (TUT). The competition is open to undergraduate students at TUT’s Department of Visual Communication, Faculty of Arts and Design and the winner will be announced at WineLand Media’s 30 Under 30 Awards on June 15.

The TUT Integrated Communication Design students will develop a cutting-edge wine label design that factors in the design process and strong ideation that must also speak to contemporary printing processes as well as finishing, including foils, varnishes, die-cuts, and embossing. One winner from the competition will be awarded the R30 000 prize money and flown to Cape Town to be recognised at the WineLand Media/ROTOCON prestigious 30 Under 30 Awards luncheon where they will also receive a certificate from ROTOCON about their label printing and finishing knowledge.

‘As a sponsor of WineLand Media’s 30 Under 30 Awards for the fourth consecutive year, ROTOCON is adding to the spirit of the event with this competition to also recognise the creativity and technical intricacies behind a wine label’s design and inspire young students with brand-driven innovation in this industry,’ says Banie Stafford of B Creative, ROTOCON’s marketing and branding agency.

The winning label design will be printed on a press with auxiliary technologies, all represented by ROTOCON, and applied to wine bottles for presentation at WineLand Media’s 30 Under 30 Awards.

‘The partnerships between industry and the university are of critical importance for our success,’ says Herman Botes, head of the Department of Visual Communication. ‘We are excited to add this vibrant partnership to this mix that will enable our students to be industry ready in the niche area of wine label design and production.’

The 30 young individuals to be recognised by WineLand Media are from a variety of fields in the wine value chain, from soil scientists, harvest assistants, winemakers and academics to sommeliers, wine marketers, PR and marketing experts, and brand ambassadors.

‘These young voices will become the leaders of tomorrow and we want to tell their stories, share their visions for our industry and help shape their future,’ concludes Wanda Augustyn, editor of WineLand.

Celebrating the launch of a wine label design competition for undergraduate students at the Tshwane University of Technology are Herman Botes, head of the Department of Visual Communication and Banie Stafford of B Creative, ROTOCON’s marketing and branding agency (pictured above).

Labelling technologies showcased in Southeast Asia

EARLIER this month, ROTOCON director Patrick Aengenvoort attended Labelexpo Southeast Asia in Bangkok, Thailand. ‘Although the show was smaller than its European counterpart that takes place in Brussels, Belgium – which is traditionally attended by South African industry role players – the same cutting-edge technologies were on display by our ECOLINE AND CHROME machinery partners and principals, Erhardt + Leimer (E+L) and Domino Printing Sciences in Bangkok,’ he remarks.

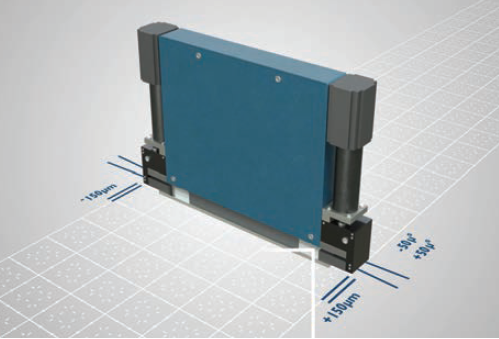

Patrick explains that E+L’s SMARTSCAN system represents the perfect complementary quality control system for ROTOCON’S range of ECOLINE RSI slitter rewinders to satisfy label printers/converters’ ever-greater demand for cost-effective efficiency, quality, and accuracy.

E+L’s SMARTSCAN system combines web monitoring, 200% inspection and label counting with ease of use via a one-touch button set-up. SMARTSCAN permanently checks the entire web width and length to detect and intelligently classify defects as printing errors, missing labels, unremoved matrix, splice points, and flags.

According to Patrick, SMARTSCAN achieves this with double image capture – via two LED illumination methods rather than two cameras – to generate images of the web and evaluate them. This 200% inspection system makes it possible to detect defects in paper, transparent or clearon- clear labels, and glossy film material printing that aren’t visible with classical incident illumination (100% inspection).

Progressive variable data printing

Domino was showcasing its modular K600i digital inkjet printer – based on sixth generation technology and a global install base of 1 000 – as the perfect cost-effective and 600dpi print quality solution to fulfil the growing demand for variable data printing (VDP) across a wide range of substrates.

Patrick explains that the K600i is capable of printing simple alpha-numeric text and sequential numbering to a wide range of industry-standard machine-readable barcodes and 2D codes, including QR and Data Matrix codes at speeds of up to 200m/min. These are used for logistics and reverse logistics in e-commerce and online retail, for ‘track and trace’ applications in the food and beverage sectors, and for security applications, including brand protection, in the pharmaceutical and tobacco sectors.

He also emphasises that this monochrome UV inkjet printer offers choice and flexibility and is available in seven different print width formats, ranging from 108mm to 782mm, in either a standard single print bar or the high-speed dual bar configuration. It can be retrofitted onto most conventional printing presses and finishing lines. The K600i can be used with Domino’s UV-curable, LED-curable and aqueous pigmented ink sets, with a high opacity white ink, a fluorescent ink and a clear varnish.

The K600i incorporates Domino’s intelligent Technology (i-Tech) features ActiFlow, CleanCap and StitchLink, which combine to create a flexible and highly reliable digital printing system with superior performance that requires minimal maintenance.

i-Tech ActiFlow is a continuous ink circulation system that degasses the ink, preventing air bubbles and blocked nozzles for superior jetting performance and resulting in fewer rejects, less maintenance and reduced downtime.

The i-Tech CleanCap automated print head cleaning and capping station maintains optimum reliable print nozzle performance with reduced start-up time and minimal operator intervention.

i-Tech StitchLink offers automated print head alignment for accurate registration and seamless print across the full web print width.

ROTOCON returns to Propak East Africa

ROTOCON is exhibiting for the second consecutive time at Propak East Africa – which takes place from March 14 to 16 in Nairobi, Kenya – because it is the largest dedicated packaging, plastics, printing and processing industry exhibition in the region.

The organisers, Montgomery Group East Africa, expect more than 5 500 visitors to engage with professionals from more than 35 countries. Visitors to ROTOCON’s stand (D21) can learn more about the company’s ECOLINE series of equipment for label printing, inspection and finishing in addition to auxiliary solutions for print production such as a plate mounter and anilox roller cleaner.

Michael Aengenvoort, ROTOCON Group CEO, is a presenter at the complementary conference programme on March 15, where he will discuss ‘Brand building for long-term customer partnerships’.

‘We are pleased to exhibit once again at Propak East Africa,’ says Michael. ‘There is tremendous growth potential in Kenya and its neighbouring countries. Our ECOLINE label finishing machines combined with solutions from our principals and our commitment to in-depth customer consultation and reliable after-sales service and technical support can help these printers compete more effectively.’